Products

On-Off Valves

On-off ball valves are shutoff valves suitable for use in various types of processes, from oil and gas to chemical and petrochemical, power and other industries.

The production range features different pressure classes (up to ANSI 2500 and API 15000) and sizes up to 60". Valves can be made in a range of materials from carbon steel to the most special alloys, suitable for even severe operating conditions. Depending on the application there is a choice of bolted or welded body, special coatings, special gasket materials, extensions for high and low temperature use, and generally a wide range of customizations.

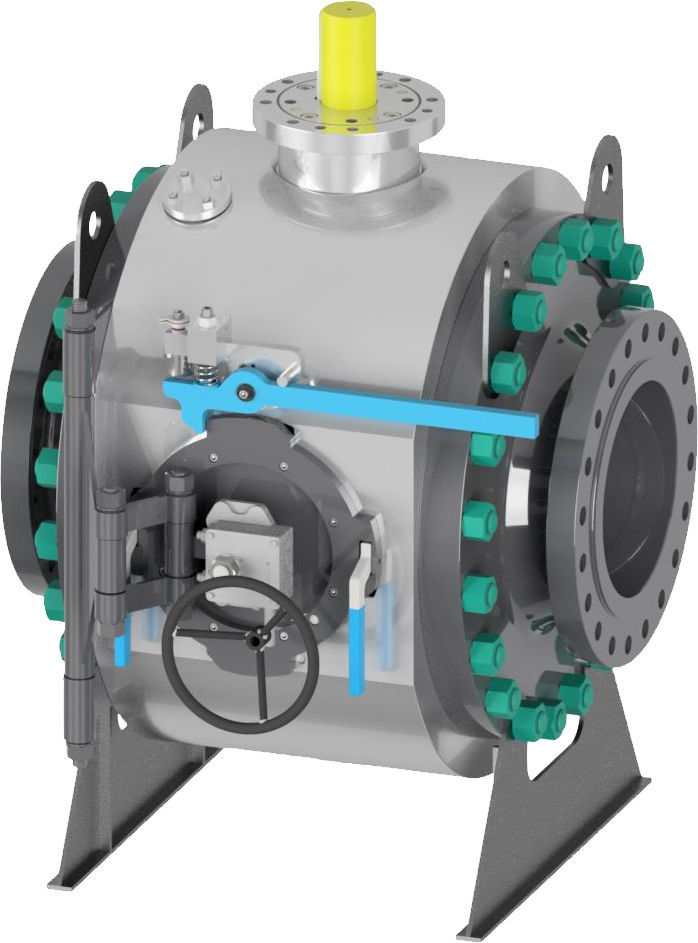

Trunnion - On-Off Floating - On-OffThe configuration of a side entry valve involves a pressure containing shell of 2 or 3 parts. The term side refers to how the components are assembled sideways before closing the pressurized enclosure. Metal components are made from annular or solid forgings or from bar based on applicable specifications. Soft materials are selected to ensure the best performance in service.

The obturator construction can be supplied in floating or trunnion versions.

The floating is the basic version of the ball valve, typically suitable for medium to low pressure applications in a limited size range (6").

The trunnion version, with a more elaborate design allows control of the effect of pressure on the operating torque and covers a wide range of pressure classes and sizes (up to ANSI 2500 pressure class/15000 psi and up to size 60").

Side entry valves are available in the following versions:

In the top entry valve, the pressurized body consists of single piece that also includes the connection ends with the pipeline. This configuration allows maintenance to be carried out without having to remove the valve from the line: by disassembling the cover, it is possible to access the internal components and proceed to their replacement.

Typically, materials made by casting process are used for the body, while the other metal components are made from ring or solid forgings or from bars based on applicable specifications. Soft materials are selected to ensure the best in-service performance.

Special tools are usually required for in-line maintenance activities.

Based on customers' technical requirements, TIV Valves can offer bodies from forgings, bars, or castings.

Top entry valves can be made in sizes from 2" to 48" and pressure classes up to ANSI 2500/15000 psi.

Top entry valves are available in the following versions:

Pig

launcher/receiver valves

PIG valves are used in all applications where the pipeline needs to be cleaned periodically. It is an excellent alternative to the conventional pigging method, allowing pigs to be fed in and retrieved safely and easily by the operator, reducing space requirements, initial investment and maintenance costs.

The valve, depending on how it is installed, can be either launcher or receiver (the same type of valve can be used to launch the scraper or to receive it).

TIV's pig launcher and receiver valves are trunnion ball valves, a configuration that extends seat life and saves time by being quarter-turn valves.

The design can be customised to handle PIGs of different configurations and lengths (up to 2 times the pipeline diameter).

Valves are available in sizes from 2" to 40" and pressure classes up to 2500.

Applications:

Compared to other control valve types, Deltaflux control ball valves ensure the following advantages:

Deltaflux

TIV Deltaflux is a control ball valve designed to control and modulate flowrate and/or pressure drop of the process fluid through the line.

Deltaflux are customized, high-quality and reliable control valves for a wide range of application, from traditional Oil & Gas (upstream, midstream and downstream) to green and renewable energies services.

Deltaflux standard version is similar to a on-off ball metal seated ball valve, where the downstream seat is replaced with a control element realized with a fixed spherical cap properly drilled to manage the pressure drop across the trim. The trim design is optimized to fit the process conditions specified by the customer. The design of a control valve is a challenging task due to the potential risk of cavitation, flashing, severe erosion phenomena, high noise emissions, etc.

DeltafluxThe side entry valve configuration involves a pressure casing consisting of 2 or 3 parts. The term side refers to the mode of side assembly of components prior to closing the pressurized enclosure.

Metal components are made from forgings or castings according to applicable specifications to ensure sealing performance over time in modulating service. Sealing between the ball and seat is metal-to-metal and is achieved through tungsten carbide coatings. Soft materials are selected to ensure the best performance in service.

The plug construction is provided in a trunnion version that ensures greater control accuracy, minimizes vibration and consequently noise in service.

The Deltaflux range covers a wide range of pressure classes and sizes (up to ANSI 2500 pressure class/15000 psi and up to size 48").

Side entry valves are available in the following versions:

In the top entry valve, the pressurized casing forms a single body that also includes the connection ends with the pipeline. This configuration allows maintenance to be carried out without having to remove the valve from the line: by disassembling the cover, it is possible to access the internal components and proceed to their replacement.

Typically, materials made by casting process are used for the body, while the other metal components are made from annular or solid forgings or from bar stock based on applicable specifications. Soft materials are selected to ensure the best in-service performance.

Special tools are usually required for service activities.

Based on customers' technical requirements, TIV Valves can offer bodies from forgings, bars, or castings.

Deltaflux top entry volves can made in sizes from 2" to 48" and pressure classes up to ANSI 2500/15000 psi.

Top entry valves are available in the following versions:

Operators

Based on customer requirements, TIV Valves can supply valves with different operator configurations.

1. Bare stem

In this case, the operating element is selected and installed directly by the customer.

TIV Valves shares the torque table, top mounting and all other necessary information with the customer.

2. Manual

Depending on the operating torque, the valves can be lever- or gear-operated.

3. Implemented

According to customer specifications TIV Valves selects the most suitable actuator for the required service.

TIV's technical department directly shares data, which allows the machine to be developed in synergy with the supplier. TIV collaborates with leading manufacturers nationally and internationally, adhering, when necessary, to vendor lists shared by customers.

At the end of procurement, the valve and actuator assembly is tested and certified at TIV Valves.

Test is carried out according to an appropriate FAT procedure to validate the design under operating conditions.

Actuators can be extensively customised in terms of type (pneumatic, hydraulic, electric, gas over oil or direct gas), control logic, power supply, accessories (limit switch, tank, partial stroke, etc.) and more.

TIV also supplies valves implemented for HIPPS systems and certified up to SIL 3.