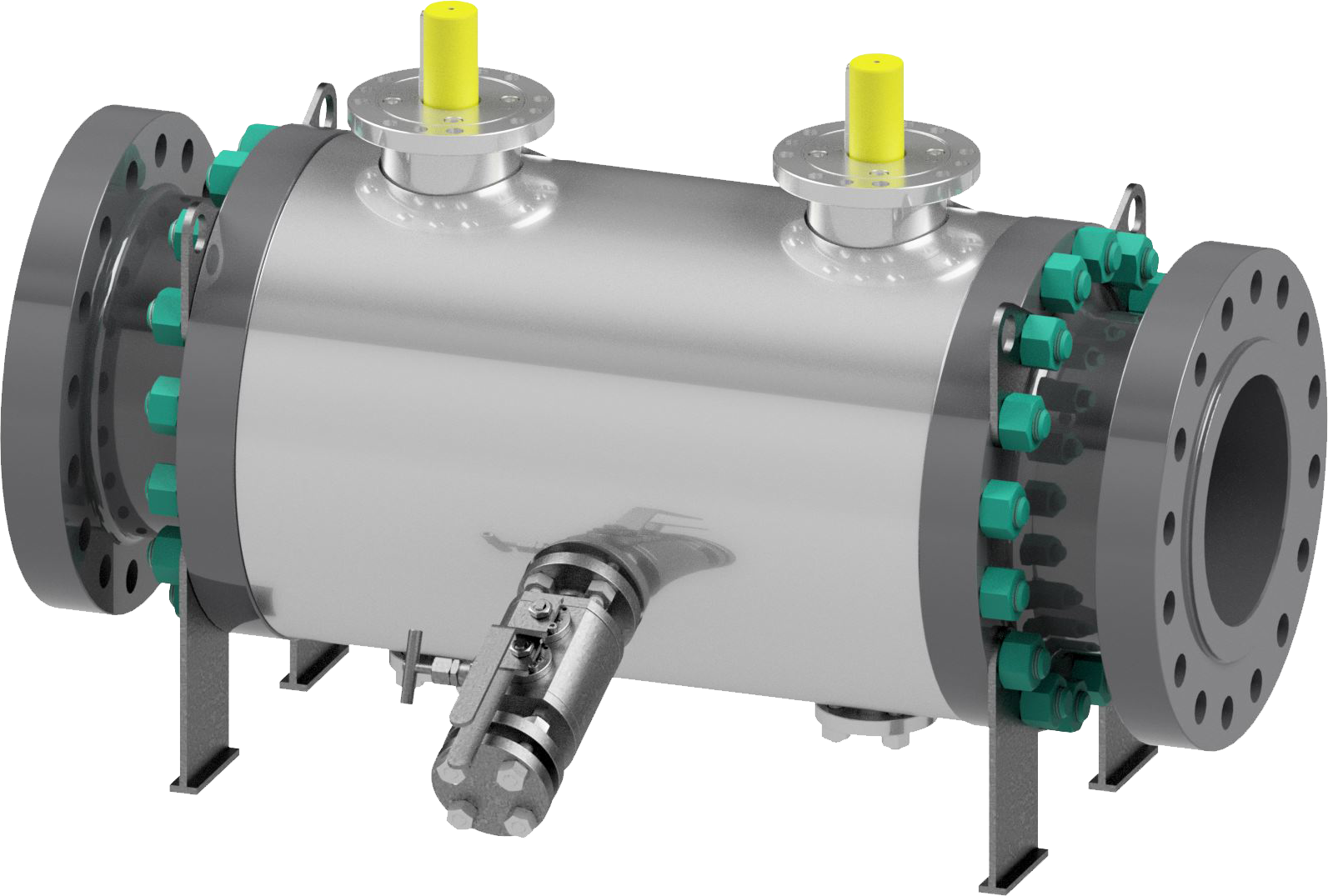

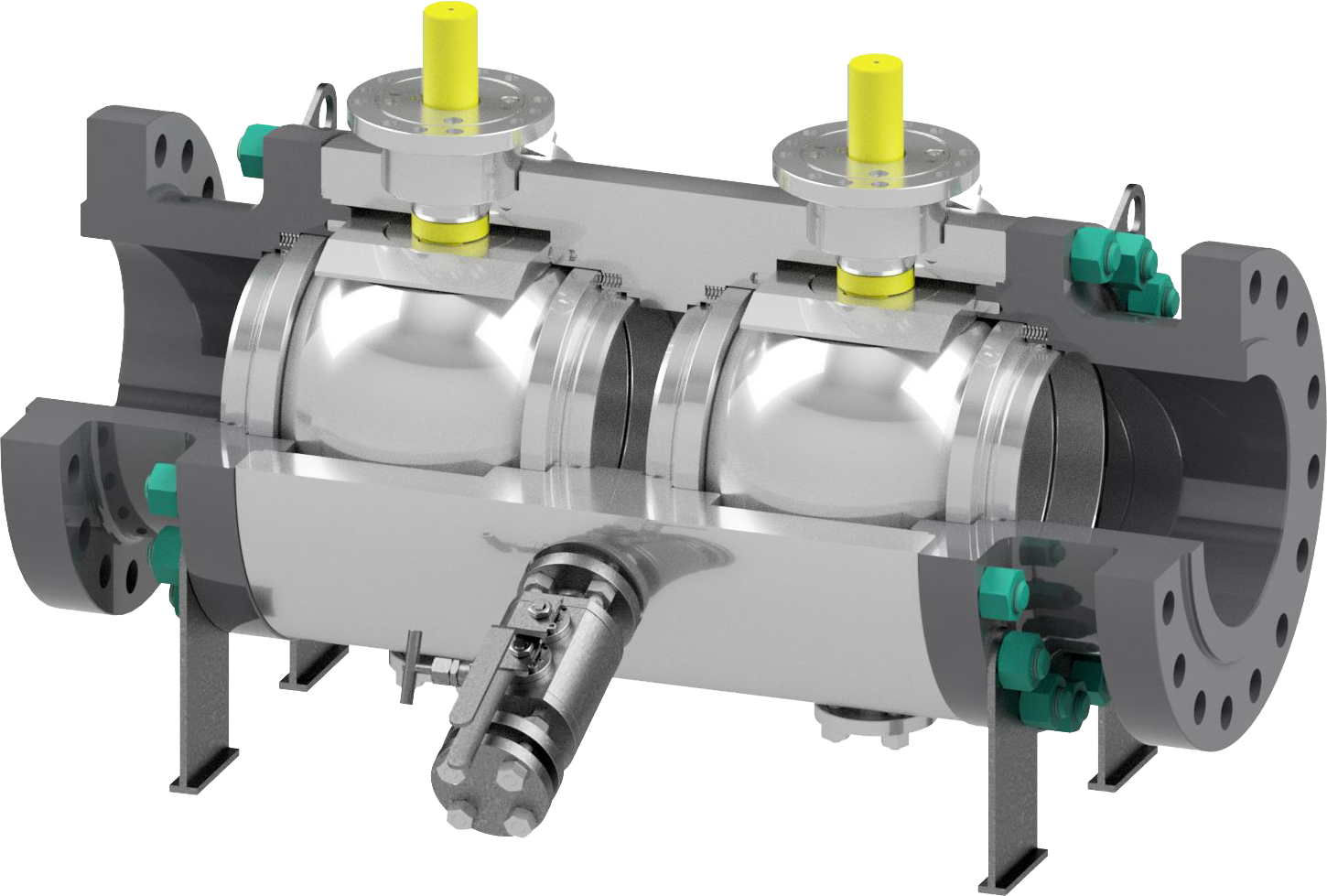

Twin Ball

The modular design allows to have two balls in one body. This design is the best solution where space and weight saving is a key factor while safety or process issues require a double seal. For an additional end to end reduction and even more cost effective solutions, compact or threaded holes flange arrangement can be selected.

Depending on the pressure, size and service you can have trunnion or floating version.

| ANSI 150 to 2500 | |

| 1/2” to 24” (NPS 15 to NPS 600) | |

| Bare stem, Manual (lever o gear operated), Motor operated (pneumatic, hydraulic, direct gas, gas over oil or electric actuator). | |

specifications |

API 6D, API 6A, API 6DSS |

| Electroless Nickel Plating (ENP), HVOF tungsten carbide coating (TCC) if metal to metal sealing is required. | |

| Low temperature carbon steel (body, connectors, ball, seats, cover, top flange); Stainless steel (stem). |